This is the second post in a mini series about shedding weight from your rigging. The goals are to minimize rope waste, reduce the number of pieces of gear carried, maximize efficiency and never sacrifice safety. Ropes from 8mm-11mm in diameter, and manufactured by Sterling Rope, Petzl and Highline Rope will be tested.

Sterling Rope generously donated 4 short lengths of static rope for some of these tests. They asked nothing in return, other than to send them the data.

Product links are at the end of the post. Please consider purchasing your rope and other caving gear from the CES, as all proceeds go to support caving expeditions and research.

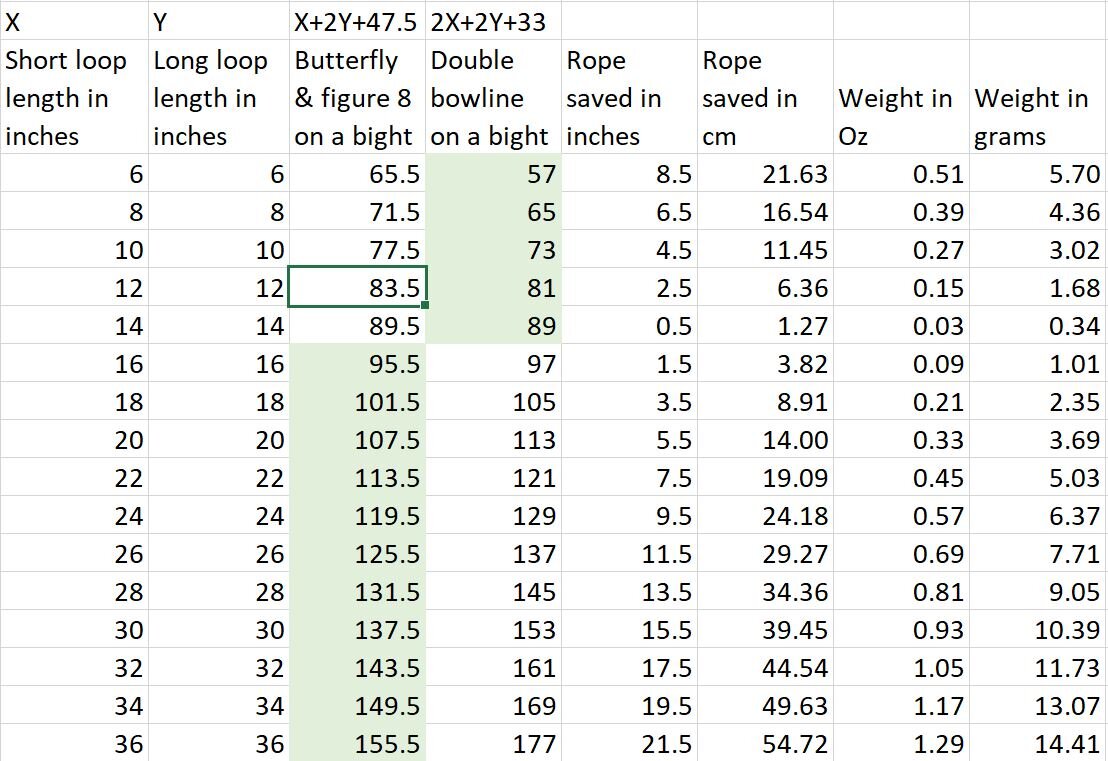

Now that we have data, what does that tell us about saving weight and rope waste? According to Sterling Rope’s website, 10mm Workpro rope weighs 4.5lbs per 100 feet or 0.06 ounces per inch (0.67g/cm). From a weight perspective, on a Y hang with 36 inch (.91m) loops/legs you might save 1.29 Oz (14.41g)! Yay?!? (a quick digression, the interrobang, “?!?” is my favorite punctuation mark) And this assumes that you cut the rope to the exact length of the pitch. However, when we look at rope waste, choosing a knot becomes slightly more relevant. In the same scenario, one saves roughly 22 inches (55cm), which might be important on a multi-pitch drop.

Here is the expanded data table:

Comparing the double figure 8 to the bowline - butterfly combo, the stats are always in favor of the later.

And finally the double bowline on a bight vs double figure 8:

My take on all this data is, knot selection is most helpful when rigging multi pitch drops in the alpine style. Choosing a knot based on weight and rope usage for Fantastic pit is not that important.

Coming up next is comparing variable length loops using more algebra and graphing!